Ladata is the UK branch of Layana, supporting European companies with early-stage engineering services and technical coordination. Leveraging Layana’s extensive manufacturing expertise and supply chain network, Ladata offers DFM consultation, mould flow analysis, CAD development assistance, rapid prototyping, and sourcing activities.

Ladata, a subsidiary of Layana Company, leverages the extensive industrial engineering expertise of one of the most innovative and fully integrated contract manufacturing OEM suppliers. Renowned for its exceptional bi-material capabilities, both Layana and Ladata excel in projects incorporating both metal and plastic parts.

Once your design is ready for mass production, you have the flexibility to choose the desired manufacturing location, either at Layana Company or at other sourced suppliers.

Design for Manufacturing Engineering Consultancy

Collaborative partnership to refine designs for manufacturability and assembly—reducing cost, risk, and lead time

Advanced simulation tools validate performance and identify issues before tooling investment

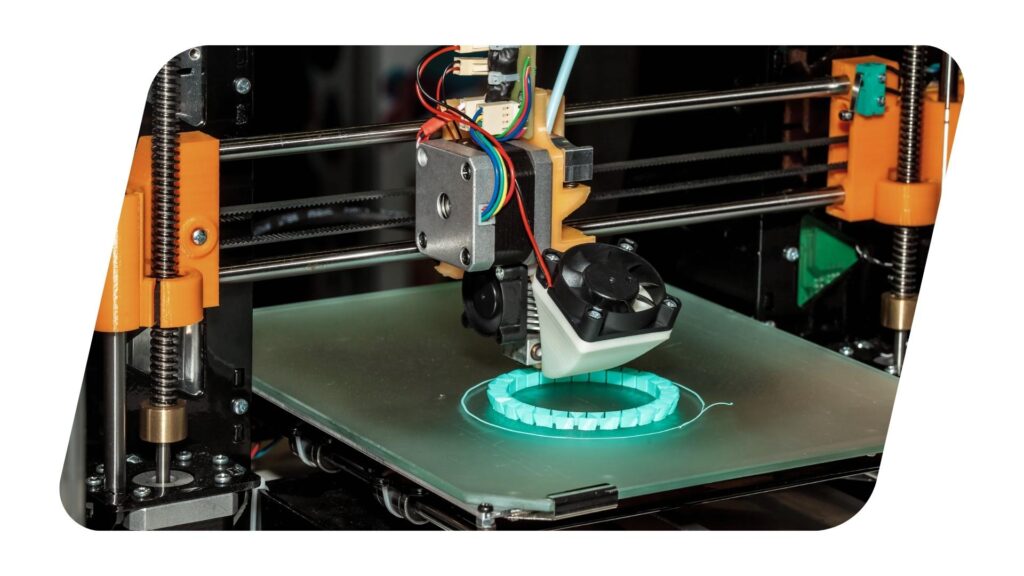

Prototyping & pilot runs, ensuring smoother transition from concept to scalable production

Cross-industry Engineering Expertise

Proven experience supporting automotive, EV, aerospace, electronics, energy, medical, and other high-demand sectors

Specialized in DFM for micro-precision and bi-material in-mould assemblies

Decades of consultancy knowledge ensuring reliable, scalable design solutions

Ready-to-Test High-Tech Equipment for Pre-production Runs (via Layana facilities)